Stärkeverarbeitung Maniok-Reibemaschine für konstante Leistung

Produktdetails:

| Place of Origin: | china |

| Markenname: | JINGHUA |

| Model Number: | GDS4*10*83 |

Zahlung und Versand AGB:

| Minimum Order Quantity: | 1 set |

|---|---|

| Preis: | 2530*1717*2270 mm |

| Packaging Details: | Standard Export Packing |

| Delivery Time: | 10 work days |

| Payment Terms: | L/C |

| Supply Ability: | 10 |

|

Detailinformationen |

|||

| Gewährleistung: | 1 Jahr | Kapazität: | Individualisiert |

|---|---|---|---|

| Gewicht: | Individualisiert | Größe: | Individualisiert |

| Spannung: | Individualisiert | Verarbeitungsmaterial: | Manioka |

| Verarbeitungsart: | Verarbeitung von Stärke | Verarbeitungstechnik: | Individualisiert |

| Hervorheben: | Stärkeverarbeitende Cassava-Grater-Maschine,Spezielle Spannung Cassava Grater Maschine,Cassava-Grater-Maschine |

||

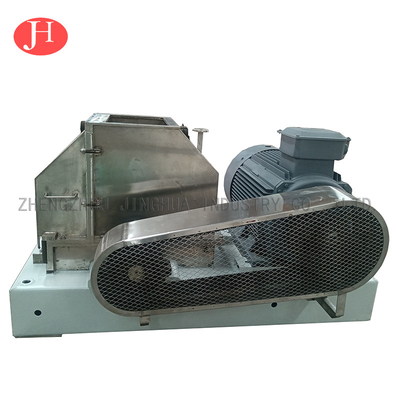

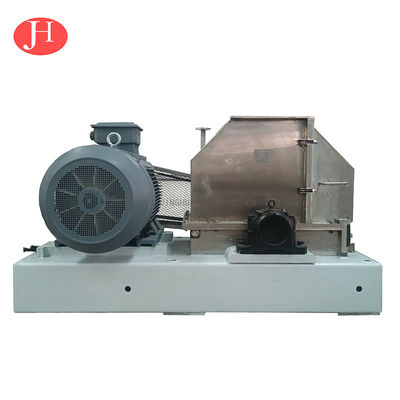

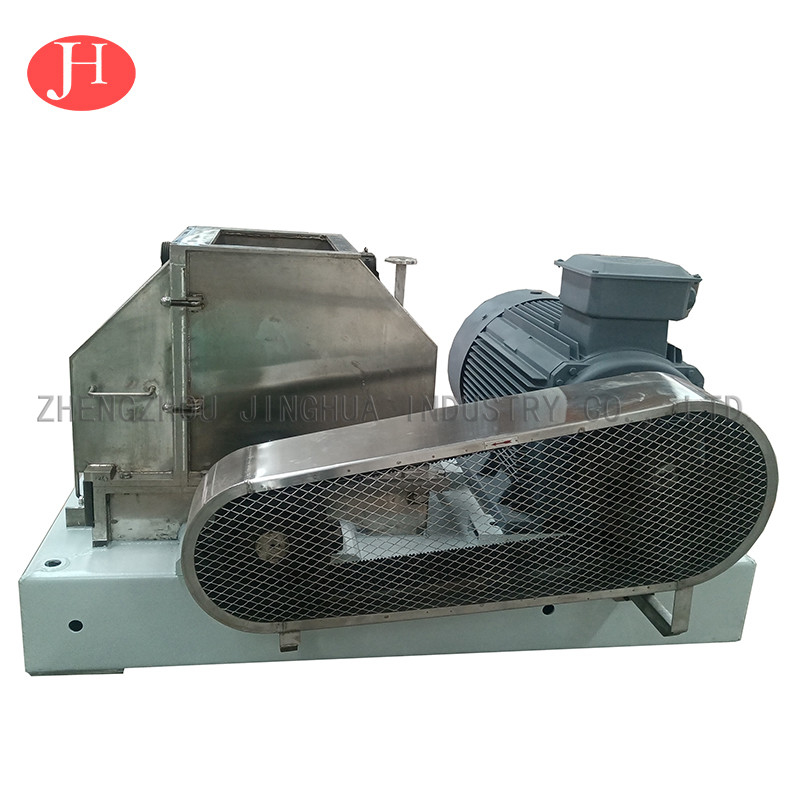

Produkt-Beschreibung

Die Cassava Starch Processing Equipment ist ein wesentlicher Bestandteil jeder Cassava-Mehlproduktionslinie und wurde entwickelt, um Cassava effizient zu hochwertiger Stärke zu verarbeiten. Hergestellt aus langlebigem Edelstahlmaterial, ist diese Cassava Stärkemaschine auf Langlebigkeit ausgelegt und widersteht den Anforderungen der industriellen Stärkeverarbeitung. Mit einer kundenspezifischen Leistungskonfiguration kann diese Cassava Starch Processing Machine an die spezifischen Bedürfnisse und Anforderungen Ihrer Produktionsstätte angepasst werden.

Diese hochmoderne Ausrüstung wurde speziell für die Stärkeverarbeitung entwickelt und gewährleistet optimale Effizienz und Ausgabequalität. Ob Sie Cassava-Stärke für Lebensmittel-, Pharma- oder Industrieanwendungen herstellen, diese Verarbeitungsanlage ist in der Lage, konsistente Ergebnisse zu liefern. Die Edelstahlkonstruktion garantiert nicht nur Hygiene und Sauberkeit, sondern bietet auch Haltbarkeit für den Dauerbetrieb.

Die Cassava Starch Processing Equipment ist äußerst vielseitig und verfügt über eine kundenspezifische Kapazität, um Ihrem Produktionsvolumen gerecht zu werden. Ob Sie ein Kleinbetrieb oder eine große Industrieanlage sind, diese Maschine kann so konfiguriert werden, dass sie Ihren Verarbeitungsanforderungen entspricht. Die Flexibilität bei den Leistungsoptionen ermöglicht es Ihnen, die Energieeffizienz und Produktivität basierend auf Ihren betrieblichen Anforderungen zu maximieren.

Mit ihrem Fokus auf die Stärkeverarbeitung ist diese Ausrüstung darauf ausgelegt, den Produktionsprozess zu rationalisieren, manuelle Arbeit zu reduzieren und die Ausgabeeffizienz zu steigern. Die Cassava Stärkemaschine ist mit fortschrittlichen Funktionen ausgestattet, um eine präzise Steuerung der Verarbeitungsparameter zu gewährleisten, was zu einer gleichbleibenden Stärkequalität führt. Dieser Automatisierungsgrad verbessert nicht nur die Produktivität, sondern minimiert auch die Fehlerquote im Produktionsprozess.

Wichtige Technologie- und Innovationsoptionen

1. Alle Teile, die mit dem Rohmaterial in Kontakt kommen, bestehen aus lebensmittelechtem Edelstahl, der die Materialien vor äußerer Verschmutzung schützt.

2. Hohe Drehzahl, hohe Liniengeschwindigkeit, hervorragende Raspelleistung, gleichmäßige Partikel und hohe Stärkeionisationsrate.

3. Der Rotor wird mit einem international fortschrittlichen dynamischen Auswuchtinstrument kalibriert, das dem G1-Standard entspricht.

4. Komponenten (z. B. Lager) werden aus Europa importiert und haben eine längere Lebensdauer.

Wichtige technische Parameter

|

Modell |

DCM8435 |

DCM8450 |

DCM8465 |

DCM1070 |

|

Drehzahl der Hauptwelle (U/min) |

2100 |

2100 |

2100 |

1470 |

|

Trommeldurchmesser (mm) |

Φ840 |

Φ840 |

Φ840 |

Φ1100 |

|

Trommelbreite (mm) |

350 |

500 |

650 |

700 |

|

Leistung (kW) |

110 |

160 |

200 |

250 |

|

Kapazität (t/h) |

20-23 |

30-33 |

35-40 |

40-45 |

|

Abmessungen (mm) |

2170x1260x1220 |

2170x1385x1250 |

2170x1650x1380 |

3000x1590x1500 |

Die komplette Maschine besteht aus Rotor, Raspelklinge, Motorbasis, oberer Abdeckung, Seitenabdeckung, Lagerbasis, Getriebe, Motor usw.

1. Die Motorbasis stützt alle Komponenten, auf denen Rotor und Lager befestigt sind.

2. Der Rotor besteht aus speziellem Edelstahl, gleichmäßige Rillen auf der Oberfläche zur Installation des Sägeblatts.

3. Das Sägeblatt besteht aus 2 Edelstahlschichten mit einem Sicherungsstift und einem Sägeblatt.

4. Auf beiden Seiten des Rotors sind 2 kombinierte Raspelklingen angebracht, wodurch eine bidirektionale Drehung des Rotors erreicht und eine höhere Zerkleinerungsrate erzielt werden kann.

Echter Anwendungsfall

![]()

Vorverkaufsservice

1. Vorstellung detaillierter Merkmale und Anwendung der Produkte für den Kunden.

2. Auswahl wirtschaftlicher und praktischer Maschinen für den Kunden.

3. Bereitstellung von Betriebsdaten der zugehörigen Maschine.

4. Bereitstellung von Mitteln zur Leistungserprobung für den Kunden.

5. Flussdiagramm und Fabrikdesign-Layout.

Verkaufsservice

1. Empfehlung der für die Installation der Maschine erforderlichen technischen Bedingungen.

2. Rechtzeitige Kommunikation des Fertigungsfortschritts der Maschinen mit dem Kunden.

3. Projektplanungs- und Designleistungen.

Kundendienst

1. Schulung der Wartung und des Betriebs der Geräte persönlich.

2. Installation und Inbetriebnahme der Geräte, bis alles funktionsfähig ist.

3. Ein Jahr Garantie und Bereitstellung von langfristigem Wartungsservice und Ersatzteilen.

4. Technische Unterstützung für den Kunden bei der Entwicklung neuer Produkte.

5. Ingenieure stehen zur Verfügung, um Maschinen im Ausland zu warten.

Verpackung: Holzkisten / kundenspezifisch

Lieferung: 25 Tage nach Erhalt der Vorauszahlung (pünktlich gemäß Vertrag)

Q1: Ist Ihr Unternehmen eine Fabrik oder ein Handelsunternehmen?

A: Unser Unternehmen ist eine Fabrik in der Provinz Henan mit Exportlizenz und wir betreiben seit über 20 Jahren professionell Exportgeschäfte.

Q2. Was ist Ihr Hauptgeschäft?

A: Zhengzhou Jinghua widmet sich der Stärkeverarbeitungsmaschine. Die Maschine der Stärkeverarbeitungslinie, wie z. B.: Cassava-Stärkelinie, Cassava-Mehl-Linie, Kartoffel-Stärkelinie, Süßkartoffel-Linie, Weizenstärke, Sago-Linie und Garri-Linie

Q3: Wo befindet sich Ihre Fabrik? Wie kann ich sie besuchen?

A: Unsere Adresse: Kreuzung Zhengyun Road und Guanggu Road, Guangwu Town, Zhengzhou City, Provinz Henan, China.

Q4: Können Ihre Produkte sichergestellt werden?

A: Unsere Maschinen haben alle ISO9001:2001 bestanden und verfügen über ein CE-Zertifikat von SGS, TÜV.

Q5: Wenn wir Ihnen unser Fabriklayout zeigen, können Sie uns dann helfen, die gesamte Prozesslinie zu entwerfen?

A: Ja, unsere erfahrenen Ingenieure und technischen Mitarbeiter können Ihnen helfen, das Layout und die Installation der gesamten Prozesslinie basierend auf Ihrer tatsächlichen Situation zu arrangieren;

Q6: Wenn wir Muster neuer Produkte haben, können Sie uns dann helfen, die Maschine zu analysieren und zu entwerfen?

A: Ja, unsere technische Abteilung kann Ihnen helfen, die neuen Produkte, die Sie angeboten haben, zu analysieren, zu entwerfen und zu testen.